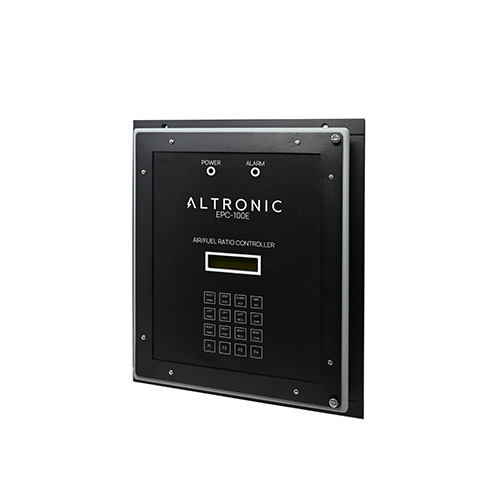

The EPC-110/120/100E/150 Air/Fuel Ratio Controls are applicable to most carbureted natural gas-fueled engines.

This universal line of emission control systems includes three specific models – two of them for stoichiometric applications using a catalytic converter (EPC-110/120 and EPC-100E), and a third model used exclusively on carbureted, lean-burn engines (EPC-150). The EPC control systems utilize microprocessor technology, thus allowing for the execution of sophisticated control strategies, and a high-level of application-specific customization. This advanced control and setup functionality is coupled with a complete line of precision, industry-proven fuel control valves. Taken together, these capabilities collectively assure the user of long-term air/ fuel ratio stability and reduced engine exhaust emissions. While stoichiometric and lean-burn engines require fundamentally different oxygen sensing technologies, all EPC systems operate on the basis of closed-loop control to a setpoint utilizing data from an exhaust-mounted oxygen sensor as feedback. With the exhaust oxygen setpoint for lowest emissions entered into the controller, the EPC unit precisely controls the flow of fuel to the engine through the stepper motor valve(s) so as to maintain the target oxygen level during engine operation.