Author: Don Ford

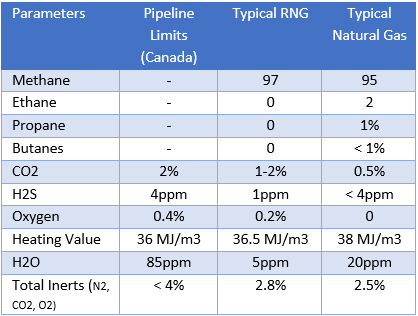

Transmission and utility companies are adding Renewable Natural Gas (RNG) to their pipelines to offset their overall carbon intensity. RNG is the refined form of biogas, which is a methane-rich byproduct from the decomposition of organic matter, such as in landfills, wastewater treatment, or farm waste processing. Refined RNG is mixed with natural gas and must meet specifications required by the pipeline to ensure that gas quality is not affected. Critical measurements include flow, heating value, H2S, O2, H2O, and inerts.

Measurement of RNG

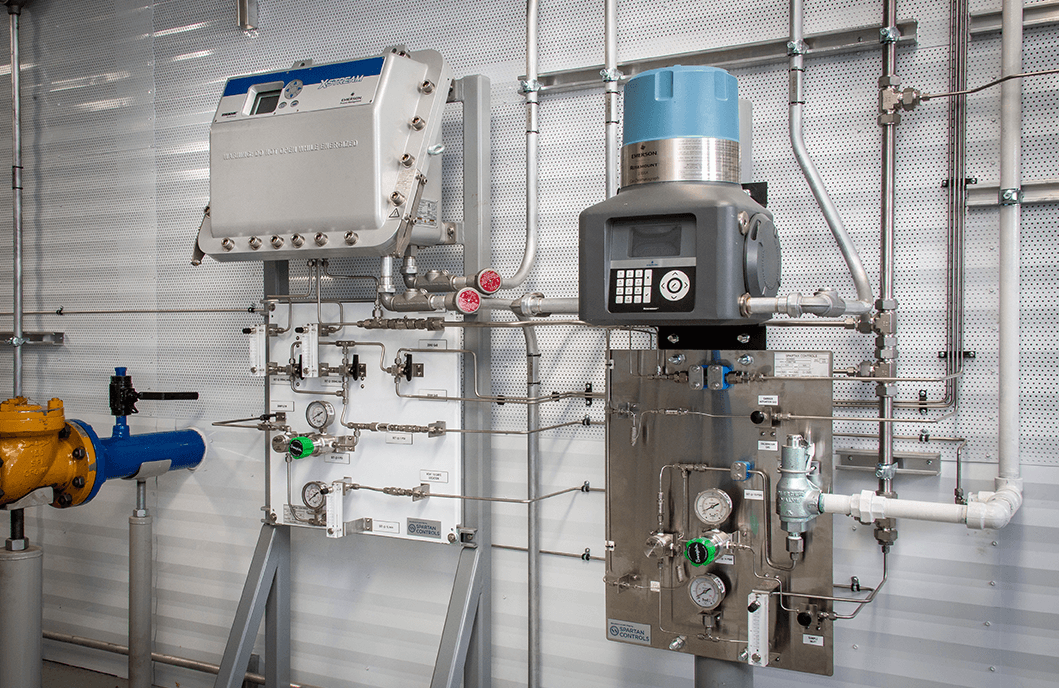

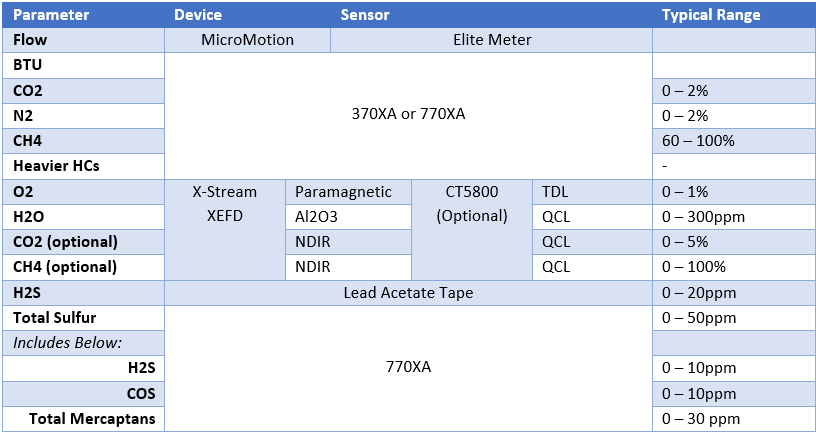

The RNG measurement begins with a flow meter. At Spartan Controls, we prefer to use a MicroMotion Coriolis meter. These devices provide high accuracy with high turndown, and they are now approved by Measurement Canada for use in gas custody transfer applications. The Smart Meter Verification software on the MicroMotion provides a self-checking algorithm that can run automatically without interrupting the measurement.

A Gas Chromatograph (GC) is a must for RNG, as it provides several key quality parameters, including N2, CO2, and Heating Value (BTU). The Rosemount 370XA is a low-maintenance, modular GC that monitors all these components and provides a high-accuracy Heating Value output with self-checking and self-correcting algorithms. It is also available with Measurement Canada approval for gas custody transfer.

Moisture and oxygen are continuously monitored via the Rosemount X-Stream Enhanced analyzer. This system incorporates online paramagnetic oxygen and aluminum oxide sensors for H2O measurement. The X-Stream is capable of automatic calibration and provides detailed diagnostic data. Other components can be monitored using this system, including CO2 and CH4 through infrared sensors. Another option is to use a Rosemount CT5800 spectrometer, which provides direct laser measurement of parameters such as O2, H2O, CO2, and CH4.

Moisture and oxygen are continuously monitored via the Rosemount X-Stream Enhanced analyzer.

In some cases, Total Sulfur is required, and is available via a Rosemount 770XA GC. This analyzer utilizes a micro Flame Photometric Detector for detecting low levels of sulfur. The 770XA is a Class I Div 1, 24VDC device that doesn't require instrument air, making it ideal for remote installations. The total sulfur measurement can be combined with a standard pipeline C6+ analysis in the same GC, eliminating the need for multiple analyzers.

Spartan Controls' solution also includes remote monitoring with our SpartanPROTM Empowered Services for all Rosemount and MicroMotion devices. This enables a swift response to any alarms or alerts from the devices, which can help bring stations back online faster in the unlikely event of an alarm forcing a shutdown of RNG production.

Learn more